Machines for Additive Manufacturing

In order to better understand the basic principles of this type of production technology, the following question should be answered – what kind of problem does it solve? The key issues, which this technology addresses, are two: SHAPE AND VOLUME Shape – this technology allows you to create components in complex shapes; Volume – this technology can be used both in prototyping and small scale production.

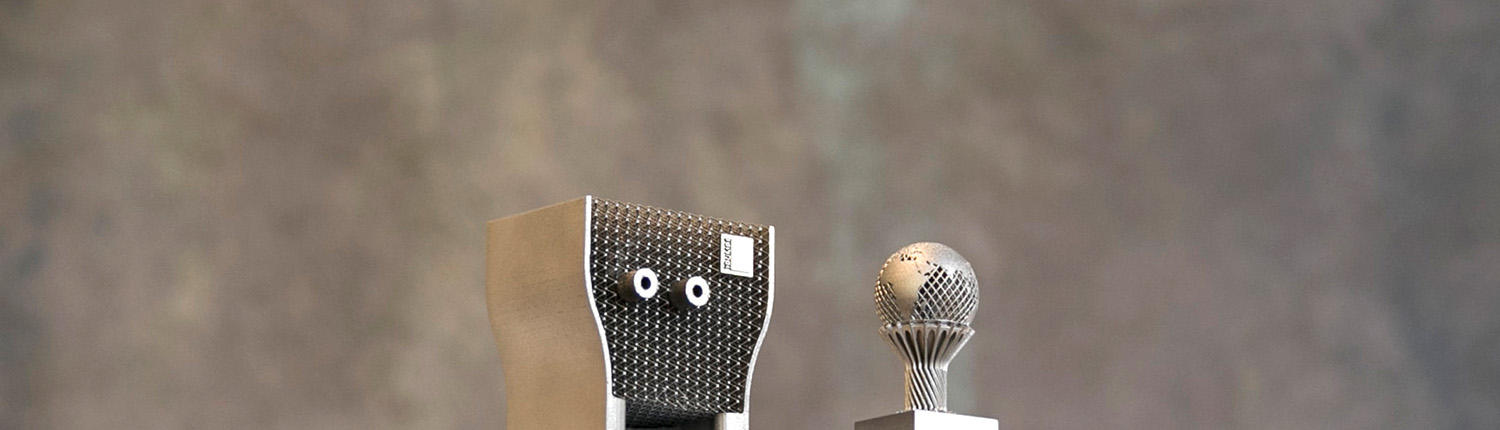

Products

The technology of additive manufacturing is the fastest growing technology, which is definitely the future of production. The range of equipment is very wide and varies greatly. Just as different as the possibilities it creates!

Starting with desktop printers, for the production of small plastic components, which are made by melting wire – to complex laser equipment, which layer by layer forms details from metal powder.

Technology

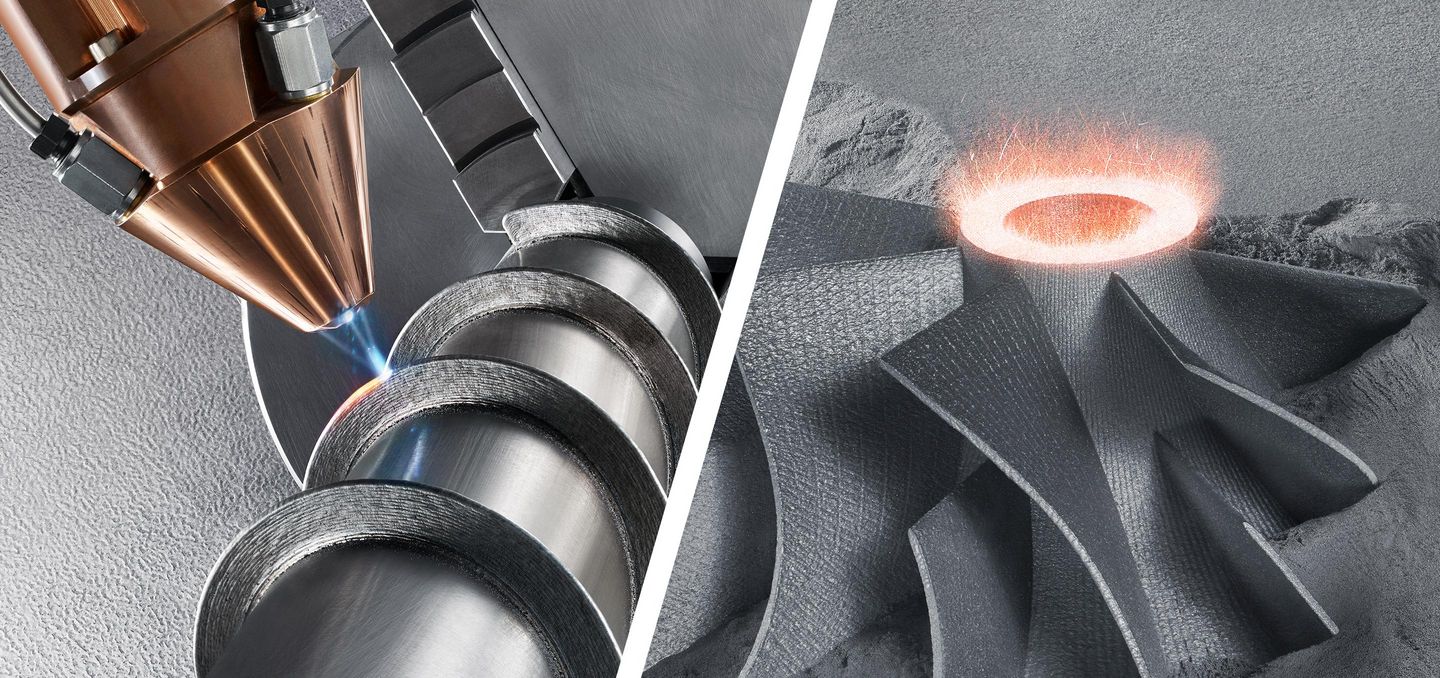

Revolutionary technology, which will not only replace some of the existing technologies, but also offers a wide range, unprecedented production capabilities.

Production is becoming more specific. Increasingly complex, small-scale products are being produced. This technology offers a solution.

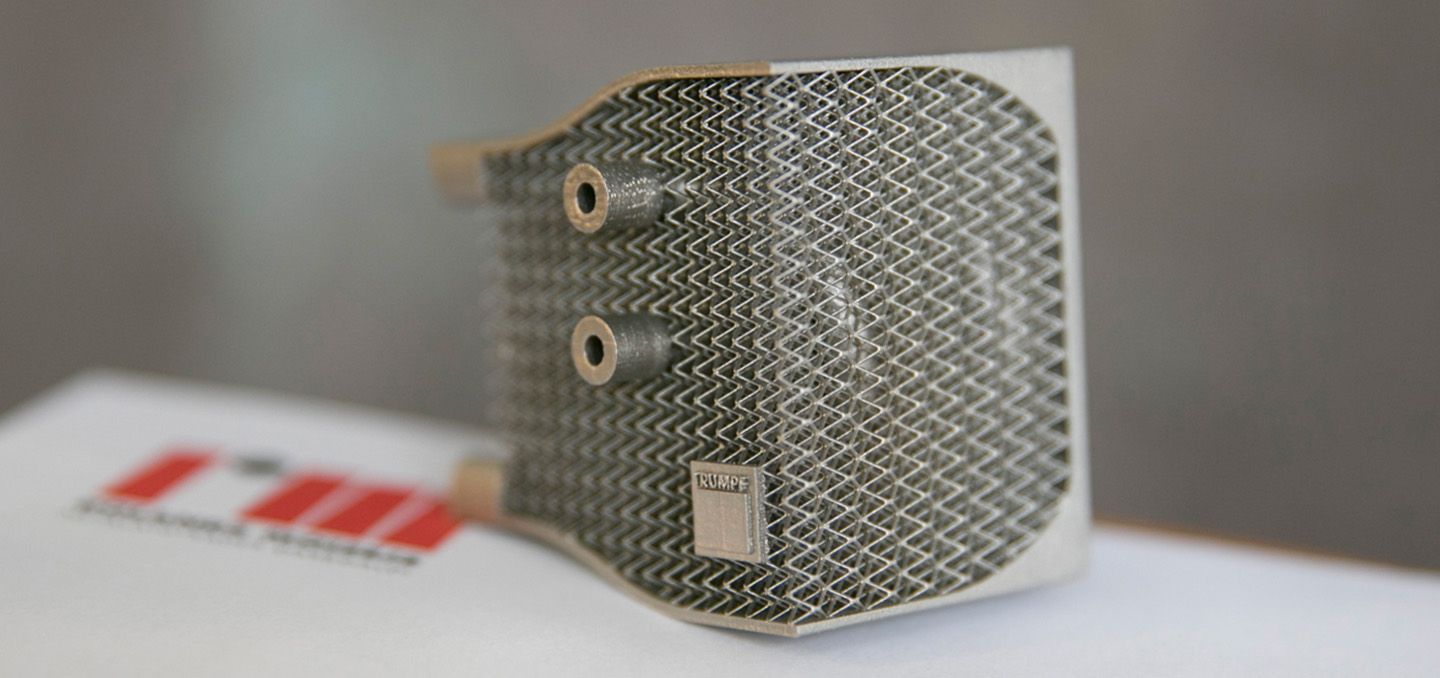

A milestone in the answer to the two questions: a complex shape and a small scale.

Shape – due to the fact that the component is produced by layering layers, it is possible to create components of varying complexity. What is important is that it is possible to form internal shapes and surfaces that can not be made by traditional production methods.

Scale – this technology is suitable for the production of prototypes specific to the production of small volume components, which are often needed to be upgraded and adapted. It is also suitable for small volume production.